Does Pipe Relining Increase Property Value?

Pipe relining fixes damaged pipes without digging or replacement. It prevents leaks, damage, and improves drainage. This increases property value and saleability for under $2000.

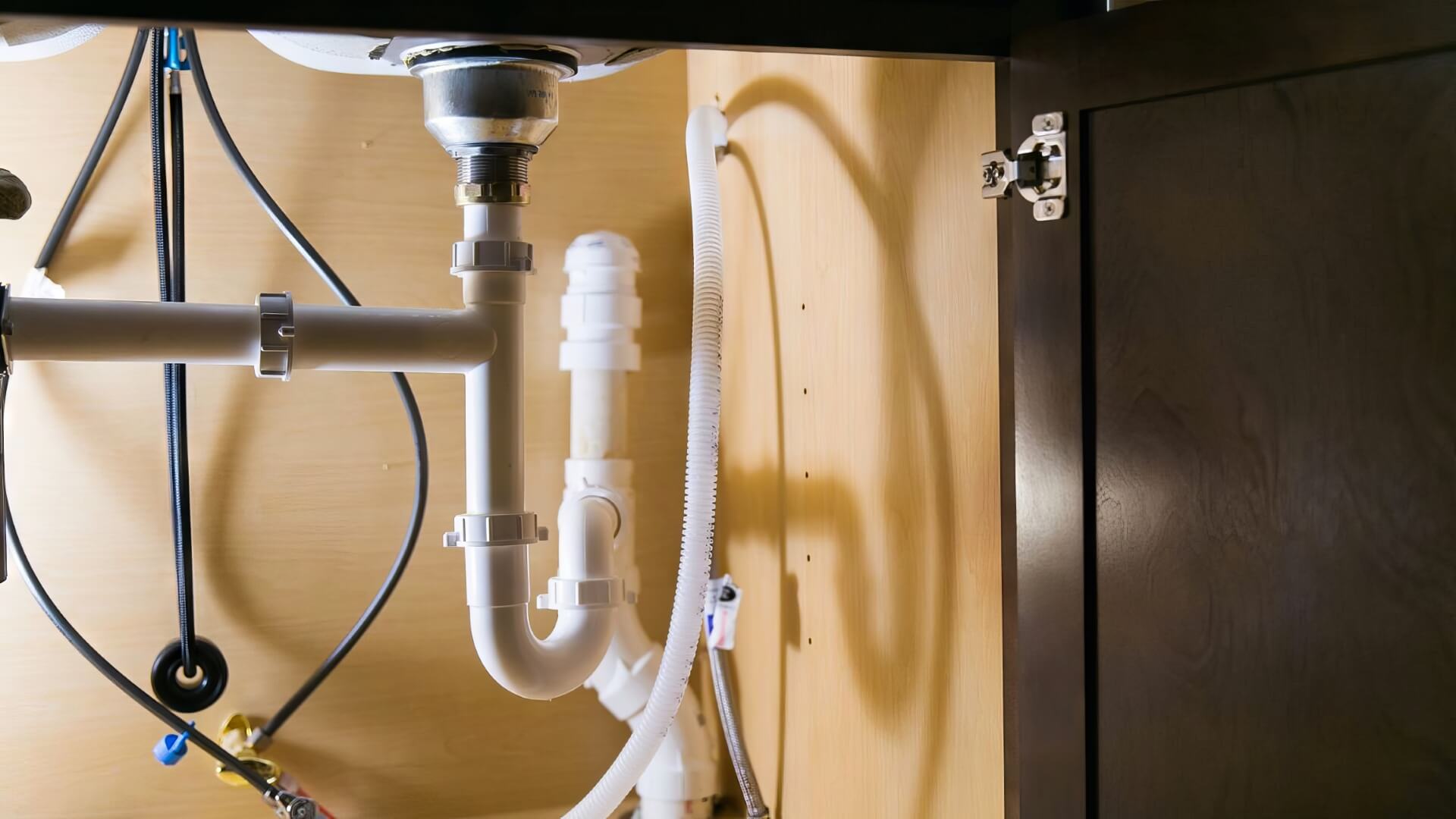

Read MorePipe relining is a state-of-the-art, trenchless technique that mitigates landscape disruption by restoring existing pipes without the need for extensive excavation. Based in Sydney, Leichhardt Plumbing delivers superior pipe relining services that minimise disruption and maintain domestic tranquillity.

This guide will discuss key factors for evaluating materials and installation quality in drain repair and pipe relining, encompassing:

Understanding the effects of damage on pipe materials helps you make informed decisions regarding repairs to your plumbing system.

There are several key pipe materials commonly used for pipe relining, each offering distinct properties and durability:

Epoxy resin liners are a top choice for preserving potable water pipes. Applied as a liquid, these sturdy plastics solidify into a resilient interior barrier, resisting corrosion, chemicals, abrasion, and root intrusion.

Meeting tough quality standards, epoxy liners are at least 3mm thick, ensuring decades of durability and suitable for temperatures up to 82°C, which is ideal for hot water pipes.

PE is a versatile thermoplastic often used for gas pipe relining. It is flexible, abrasion-resistant, and provides an effective moisture barrier against pipe corrosion. PE liners must maintain a minimum thickness of 3 mm.

PU, akin to PE, excels in refurbishing steel gas pipes. Its seamless, joint-free lining provides excellent sealing, preventing leaks and further damage to existing pipes when cured.

Similar to epoxy, PU installation involves high-pressure injection to ensure firm adherence to the inner pipe walls.

Fibreglass linings offer rigidity, making them a good choice for reinforcing collapsed pipes, though with a lower heat tolerance compared to epoxy.

A preliminary CCTV inspection is crucial to assess the suitability of fibreglass relining for your pipe network’s current condition.

The rigidity of PVC sewer pipe liners leads to more complicated installation processes, making them less common than the other materials mentioned. However, they remain an option for large diameter sewer pipes.

Selecting current plumbing techniques and premium lining components guarantees enduring outcomes. With over 30 years of experience, Leichhardt Plumbing provides expert advice on the best relining solutions after a thorough evaluation.

Before commencing sewer pipe relining, a meticulous assessment of the current pipe condition, including identifying any damage using CCTV inspections, ensures an effective relining choice and solution can be determined.

Several key indicators suggest your pipes may be better suited for relining rather than replacement:

In-pipe CCTV cameras provide a clear view of problem areas, allowing for a comprehensive assessment to determine if the pipes are viable for trenchless drain relining. We consider factors including:

Using this diagnostic information, the Leichhardt Plumbing team counsels clients on the practicality and financial benefits of relining versus complete replacement.

The relining procedure revitalises pipes internally with materials that harden in place, seamlessly renewing the pipe infrastructure.

Initially, our technicians meticulously clean the interior to prime the surface, making certain the liner integrates seamlessly with the pipe structure. Next, we utilise air pressure or inversion techniques to position the liner coated resin into your structure, creating a sturdy conduit within the existing framework for its entire length. These epoxy resin, polyethylene or other materials are flexible prior to curing, facilitating the creation of a new pipe within old through access points such as manholes or cleanouts.

Once the lining material fits into your pipes, our technicians clean up thoroughly, preventing residue from affecting the sealing process. The material cures rapidly, forming a durable, seamless new pipe within the existing structure. Using advanced technology, the liners utilised in relining can exceed a 50-year lifespan.

For homeowners, it’s vital to understand the advantages of pipe relining compared to trench digging and replacing old pipes:

With over 30 years of combined expertise in sewer pipe relining in Leichhardt, Sydney, our team is equipped to patch up trenches performing expert repairs on your sewer system with relined pipes, revamping the ageing infrastructure without extensive excavation. Get in touch for insights on how our innovative procedures can save on costs while efficiently repairing broken pipes.

In assessing a project’s quality, one must evaluate the workmanship and quality control implemented on the existing pipe during the installation process.

Look for a company that follows industry regulations and best practises, utilising the high-calibre material used in Cured-In-Place Pipe (CIPP) lining products that can last over 50 years. Addressing the critical question of 'How long does pipe relining last?' the technique involves robust epoxy or polyethylene resins that are inserted into flexible pipe liners and cure in place, forming a steadfast barrier.

Key markers of quality pipe relining application include:

Through advanced pipe relining products and compliance with industry guidelines, firms like Leichhardt Plumbing promise enhanced structural integrity, fluid capacity, and long-term performance.

Our collective 30-year expertise in Leichhardt, Sydney, in sewer relining using CIPP systems has been proven to outperform conventional pipe replacements. Get in touch to pipeslearn more about your options.

When choosing pipe relining for damaged pipes, it’s critical to select a provider with reliable guarantees for their CIPP products and workmanship. Leichhardt Plumbing uses industry-leading CIPP relining products, endorsed by manufacturer warranties of over 50 years.

These warranties affirm the structural lifespan of your pipe relining material, promising durable outcomes and protection against defects in materials and manufacturing. Trustworthy brands rigorously test CIPP products to guarantee strength and durability, instilling confidence in customers for future use.

Beyond material guarantees, Leichhardt Plumbing also provides assurances of quality installation practises, advanced training certifications for all technicians, and post-job video inspections to validate conformity to tolerances. We make sure to promptly address any concerns, ensuring you grasp the full extent of support you can expect, so no future worries will be left undone.

So to get your plumbing back to its best with dependable results from pipe relining, guaranteed to outperform traditional pipe replacement methods, trust the 30+ years combined expertise of Leichhardt Plumbing. For a comprehensive evaluation, simply call us to assess your pipe system needs.

Obtaining professional assessments and quotes from qualified specialists is crucial before embarking on any pipe relining project.

At Leichhardt Plumbing, our plumbers hold the expertise to meticulously assess your pipe system needs and present transparent recommendations. Here is an overview of what to expect when engaging our services:

Give us a ring at your convenience on 1300 349 338, or send an email to [email protected] to connect with your plumber. One of our friendly staff members will discuss your requirements, book an inspection time convenient for you and answer any initial questions.

Leveraging 30+ years combined expertise, we will assess if using pipe relining is the optimal solution for your pipe needs by restoring your existing pipe condition, type, sizing, access points and other key factors.

You will receive a transparent, obligation-free quote outlining the complete project scope for your plumbing system, and specifics like:

We prioritise clarity and detail to address your queries and alleviate concerns, ensuring transparency from the project’s start to finish.

As industry leaders in pipe relining across Leichhardt, Sydney, we deliver guaranteed results. Contact Leichhardt Plumbing to schedule your inspection and no-charge assessment today.

In conclusion, pipe relining offers a trenchless, minimally disruptive method for rejuvenating your property’s aged or damaged piping system, negating the necessity to excavate your garden. Essential factors in evaluating the quality of a damaged pipe repair include confirming the technicians’ expertise and ensuring that premium materials and correct installation procedures were utilised.

We exclusively use industry-leading Cured-In-Place-Pipe products rated to outlast traditional pipe replacements.

Contact Leichhardt Plumbing at 1300 349 338 or via email at [email protected] for a free professional assessment on whether pipe relining is right for you, all without upheaving your property.

Pipe relining fixes damaged pipes without digging or replacement. It prevents leaks, damage, and improves drainage. This increases property value and saleability for under $2000.

Read MoreThe efficiency of your hot water system can be impacted by various environmental factors. Proper insulation, temperate climates, and appropriately sized systems lead to enhanced efficiency, lower energy bills, and reduced emissions. Compare different hot water systems and learn tips to maximise efficiency.

Read MorePipe relining is the most effective way to permanently solve bad sewer smells without the need to dig trenches or damage your property. Our trenchless pipe repair specialists use specially designed pipes to reline your old, damaged pipes. This stops cracks and leaks that let sewage smells flood your home.

Read MoreLeichhardt, 2040 NSW

We will call back as soon as possible.